This report serves as a financial mirror, reflecting the detailed expenses incurred in the production process. It’s not just a ledger of numbers; it’s a narrative that tells the story of raw materials transforming into finished goods, the efficiency of production lines, and the economic forces at play within the factory walls. By dissecting this report, stakeholders can pinpoint areas of cost savings, evaluate the performance of production methods, and make informed decisions about pricing strategies. It’s a tool that offers insights from the shop floor to the executive suite, providing a comprehensive view of the production’s financial health.

Production Efficiency

All of our content is based on objective analysis, and the opinions are our own. However it is recommended to use job order costing for more than one product. Process Costing always follows the same process while job-order costing applies to each job separately.

Reviewed by Subject Matter Experts

We publish blogs, tutorial videos, free templates and more that address every aspect of managing a project and as it applies to many different industries. Here are a handful of links to stories about production management in manufacturing. This KPI analyzes and compares claiming a domestic partner as a dependent similar equipment, production lines and manufacturing plants. It’s calculated by dividing the total number of good units produced by the specific time frame. Before starting to prepare a cost report, it is important to clarify the scope and purpose of the report.

To Ensure One Vote Per Person, Please Include the Following Info

- However, while this monetary figure may seem large to produce 18 episodes, the budget also includes all the marketing and various advertising.

- A Total costs to beaccounted for (step 2) must equal total costs accounted for (step4).

- Accruing tax liabilities in accounting involves recognizing and recording taxes that a company owes but has not yet paid.

- The data should be analyzed and interpreted to generate meaningful insights and conclusions.

- It represents the total cost incurred to produce products that are ready for sale during a specific period.

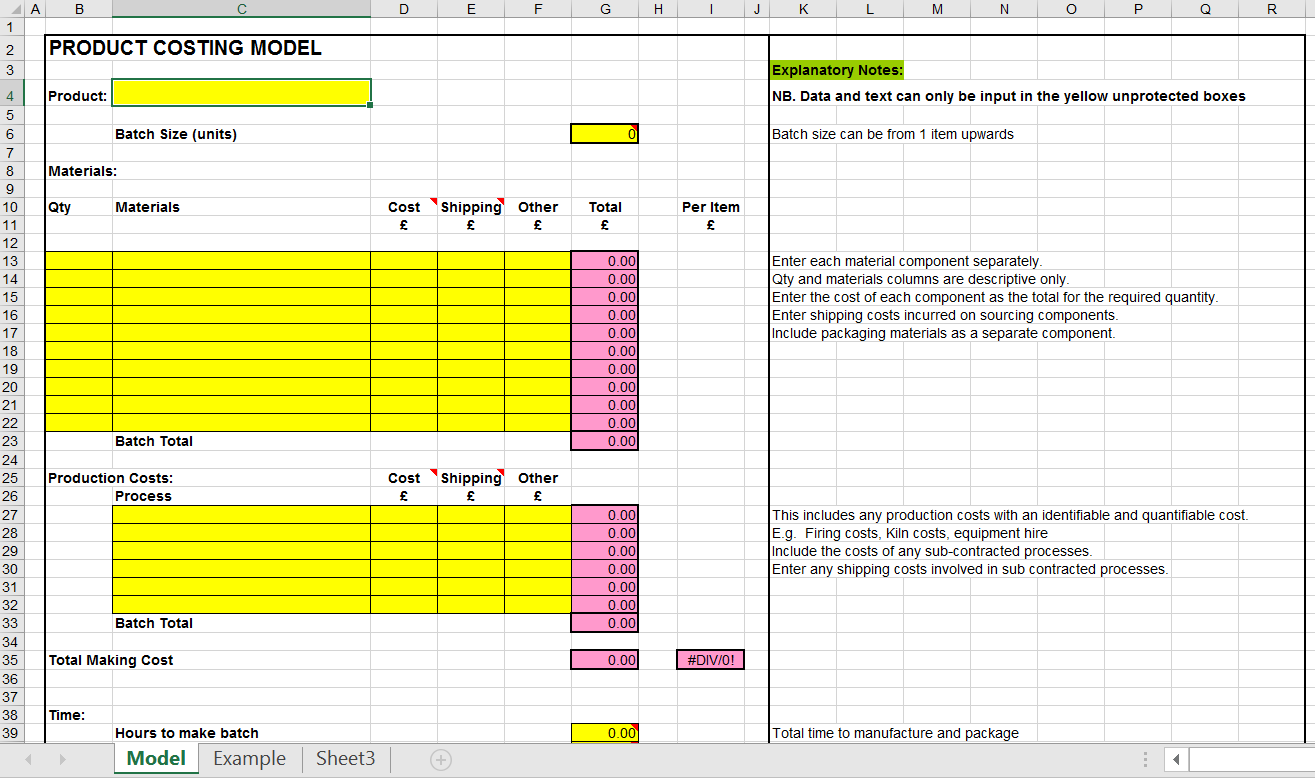

- Some examples of systematic and secure ways to record and store the cost data are using spreadsheets, databases, software applications, cloud services, etc.

A construction company that used cost reporting to monitor and control the progress and budget of a large-scale project. A baseline is a reference point that shows the original plan, budget, and schedule of the project. A contingency plan is a backup plan that accounts for the potential risks, uncertainties, and changes that may affect the project. Having a baseline and a contingency plan will help to measure the actual performance and variance of the project, as well as to adjust the plan and budget accordingly. For example, if the project encounters an unexpected delay or cost overrun, the contingency plan can provide an alternative solution or a justification for the deviation from the baseline.

Starting a nonprofit can be a fulfilling way to make a difference in the community, but it requires careful planning and consideration.

ProjectManager is award-winning project and portfolio management software that can help manage resources and monitor costs and more to identify weaknesses and improve efficiency. Production volume measures how many units are manufactured over a specific period. This is a fundamental benchmark for manufacturing efficiency and helps production managers understand the total output the factory can produce.

For example, an effective communication and presentation may involve the use of a summary, a visual aid, and a call to action. COGS is more than just a number; it’s a multifaceted indicator of a company’s operational effectiveness and financial health. By thoroughly interpreting COGS, businesses can make informed decisions that enhance profitability and competitive advantage. Trump’s goal in a second term will be to boost fossil-fuel production, his campaign has said. But he will be entering the White House after what will almost certainly be the hottest year on record in 2024.

This metric helps production managers monitor the performance of a machine over time with the goal of optimizing equipment availability while keeping costs at a minimum. Maintenance unit cost is the total maintenance expenses required to produce one product unit during a specified period. To calculate maintenance costs, divide the total maintenance costs in a specific time frame by the number of products produced during that same time frame.

We started with 750 units that were 100% complete as to materials and 60% processed, so the beginning work-in-process EUs for direct materials is 0% of 750 and for conversion costs is 40% of 750 which is 300. Establish the total inventory in production by adding units started into production to beginning work in process (what was left only partially finished at the end of the prior month). The company had 750 shells in process at the close of business on January 31. The beginning inventory of 750 plus the 3,250 pie shells worth of materials placed into production during the month gives us 4,000 total units to account for. Use our secure timesheets to ensure that labor costs align with the budget.

By dissecting the nuances of these costs, manufacturers can identify inefficiencies, adjust pricing strategies, and enhance their decision-making process. Understanding the intricacies of direct materials and labor costs is pivotal in the manufacturing sector, as these are the primary components that directly contribute to the production of goods. The accurate calculation of these costs not only reflects the efficiency of production processes but also impacts the pricing strategy, profitability, and competitive positioning of a company’s products.

Managers use COGM to set product pricing, budget for future periods, and make investment decisions. They also compare COGM with previous periods to track trends in production costs. WIP Inventory is not just a financial figure; it’s a snapshot of the production process at a given moment.